The textile machinery and equipment may cause harm to t […]

The textile machinery and equipment may cause harm to the health of personnel in the process of performing functions under the prescribed use conditions. The hazards of textile machinery and equipment may come from the mechanical equipment itself, the role of the mechanical equipment, personnel operations, and the location where the mechanical equipment is located

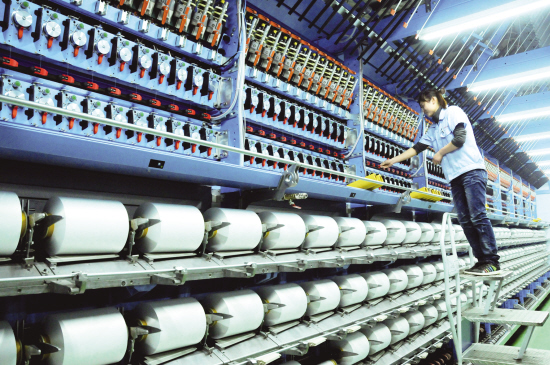

The dangers caused by textile machinery and equipment mainly include: due to its own mechanical energy function and various physical factors that may cause injury, as well as the hazards of tripping, dumping, and falling related to textile machinery and equipment; electrical hazards; temperature hazards; noise hazards; vibration hazard ; Radiation hazards, etc. The main hazards of mechanical equipment are smashing, pinching, shearing, winding, falling, falling, and electric shock. If there are many dangerous factors in the spinning machine, it is prone to typical safety accidents of textile machinery and equipment. Falling accidents are mainly caused by lack of safety supervision, command and management personnel, lack of safety awareness, or barbaric operations. They can also be caused by slipping from the body, body impact, no tool slipping, vibration, etc .; electric shock accidents are mainly due to the electrical system and The corresponding surrounding environment lacks the necessary electric shock safety protection surface; the body destruction accidents are mainly caused by the overload and instability of the body fracture and tipping, so that the body is seriously damaged and personal injury or death.

The safety hazards of textile machinery and equipment exist in the entire process of use. The occurrence of mechanical equipment accidents is the result of the combined action of various factors, mainly for the following three reasons:

1. Unsafe state of textile machinery and equipment

The safe state of textile machinery and equipment is an important prerequisite and material basis for ensuring its safe operation. The unsafe state constitutes an objective safety hazard in textile operations. These unsafe conditions, such as the unreasonable design of mechanical equipment; brutal operations in transportation and installation have damaged mechanical equipment and its parts; unqualified equipment lacking safety devices has flowed into the market; scrapped parts have not been replaced in time, lacking necessary Safety protection, poor lubrication and maintenance; operating conditions that exceed safety limits, etc. Unsafe conditions are also a direct cause of accidents.

2. Human unsafe behavior

Human behavior is affected by various factors such as physiology and psychology, and its performance is also diverse. These manifestations are: lack of safety awareness; lack of self-protection and ability to handle unexpected situations; command errors, operational errors, custody errors, etc. In the use of mechanical equipment, unsafe behavior of people is another important cause of accidents.

3. Defects in safety management

The level of safety management includes the level of safety awareness of leaders, supervision of equipment, safety education and training of managers and operators, establishment and implementation of safety rules and regulations, etc. Defects in safety management are indirect causes of accidents in textile machinery and equipment.

Hangzhou Kaili Chemical Fiber Co., Ltd. is polyester yarn suppliers and polyester dope dyed yarn manufacturers.Please contact us if you have any enquiry: https://www.klthread.com/