1. Improve the structure of the dye so that it can cons […]

1. Improve the structure of the dye so that it can consume light energy while minimizing the impact of the dye color system, thereby maintaining the original color; that is, the dye with high light fastness. The price of such dyes is generally higher than that of ordinary dyes. For fabrics with high solar requirements, the first step should be to choose dyes.

2. If the fabric has been dyed and the light fastness is not up to the requirement, it can also be improved with additives. In the dyeing process or after dyeing, add suitable auxiliary agents to make the light react before the dye when it is exposed to light and consume light energy, so as to protect the dye molecules. Generally divided into ultraviolet absorbers and anti-ultraviolet agents, collectively referred to as light fastness enhancers.

Visit:https://www.klthread.com/product/draw-textured-yarn/

Lightfastness of light-colored fabrics dyed with reactive dyes

The light fading of reactive dyes is a very complex photooxychlorination reaction. After knowing the light fading mechanism, the molecular structure of the dye is designed to consciously create some obstacles to the photooxidation reaction to delay the light fading. For example, yellow dyes containing Dole sulfonic acid group and pyrazolone, blue dyes containing methane phthalocyanine and bis-azo trichelate ring, and red dyes containing metal complexes, but still lacking bright red and solar resistance Reactive dyes for light fastness.

The light fastness of dyed products varies with the change of dyeing concentration. For fabrics dyed with the same dye on the same fiber, the light fastness increases as the dyeing concentration increases. Light-colored fabrics have low dyeing concentration and are fast to the sun. The degree drops accordingly. However, the light fastness of common dyes on the printed dye color card is measured under the standard depth of 1/1 (that is, 1% owf or 20-30g/l dye concentration). If the dye concentration is 1/ In the case of 6, 1/12 or 1/25, the light fastness will be greatly reduced.

Some people have proposed using ultraviolet absorbers to improve the fastness to light. This is an undesirable method. Ultraviolet rays need to be used a lot and can only be improved by half a level, and the cost will be much improved. Therefore, only fair selection of dyes can solve the light fastness.

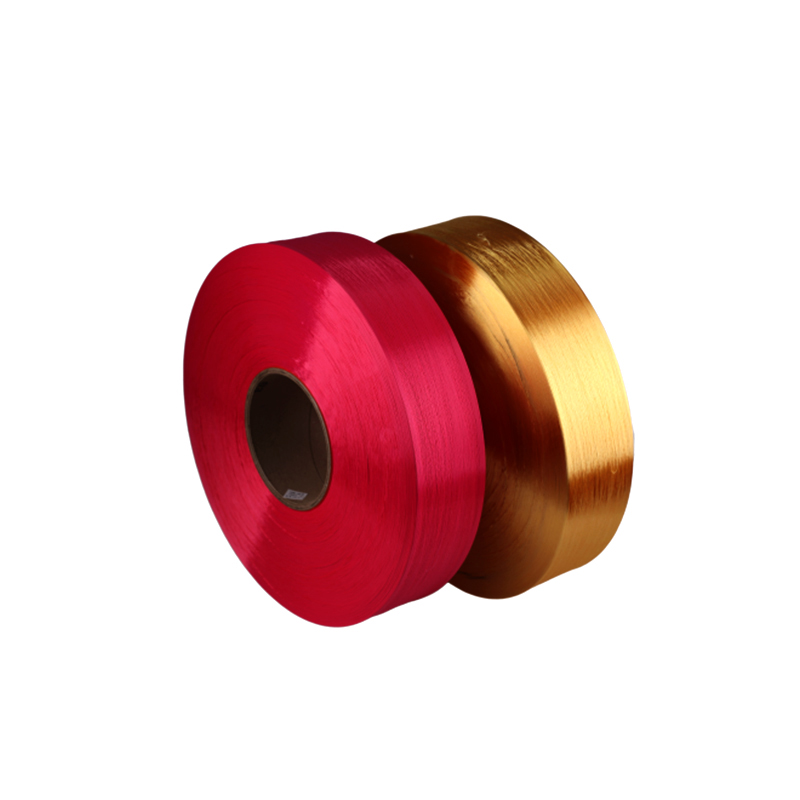

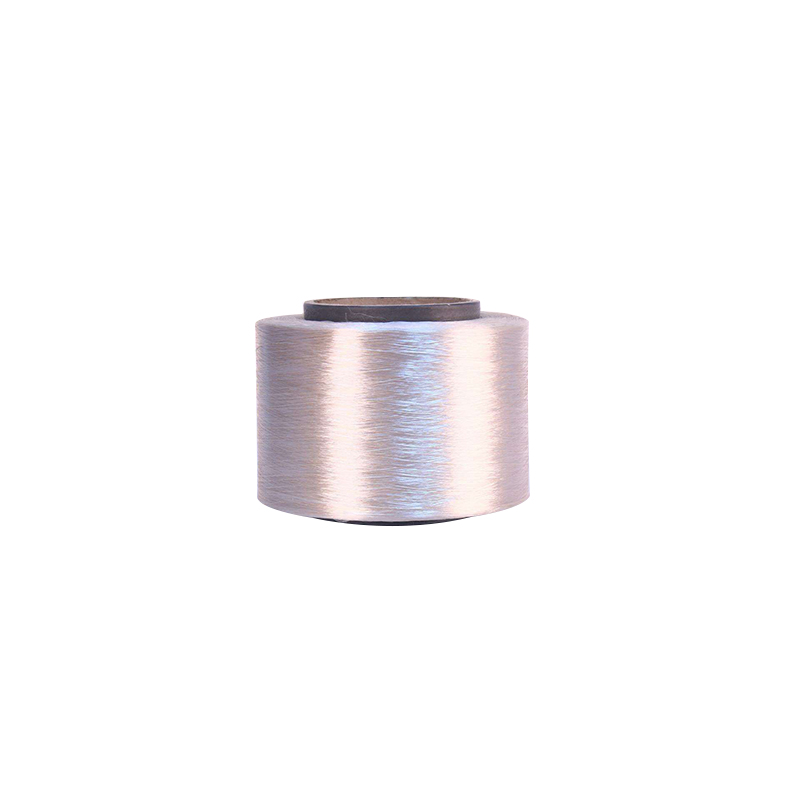

Hangzhou Kaili Chemical Fiber Co., Ltd. is a famous China polyester dope dyed yarn manufacturers